|

|

||

|

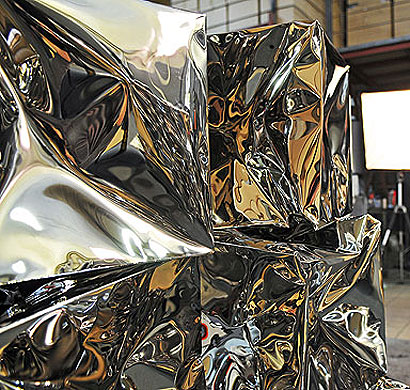

Oskar Zieta, the poster boy for contemporary Polish design, has filled Milan’s Cardi Black Box Gallery with 50 helium balloons, with a Plopp stool hanging from each. The stunt, inspired by the animated film Up (2009), is to show off the lightness of the latest version of the blow-up metal furniture that made the designer’s name. “The new stools are made of aluminium painted in pearl,” says Zieta, who also presented at the Milan Furniture Fair as part of the Young Creative Poland collective. “We want to show that the design is now much lighter but is still a durable form of construction.” Plopp, originally designed in stainless steel for Danish manufacturer HAY in 2008, is made using free internal pressure forming technology, or FIDU: a pocket of thin metal sheets is inflated at high pressure to create a three-dimensional form. “In FIDU, the great matter is how you control the form. Because it’s an uncontrolled process, you never know what the final result will be,” says Zieta. The technique, developed by Zieta as part of his research into computer-controlled machineryat the Swiss Federal Institute of Technology (ETH) in Zurich, has bred a whole range of ultra-light products with the same distinctive look: bulging shiny surfaces reminiscent of Jeff Koons’ balloon sculptures.

credit Zieta Prozessdesign The pop aesthetic of the line and the novelty of the technique shouldn’t draw attention away from the sheer impressiveness of the technology itself. Products like Plopp and the Chippensteel chair are made with steel sheets just 0.5mm thick, yet are durable enough to support the weight of someone sitting on them without deflection or movement. Zieta, who trained as an architect, is obsessed with refining his collection to make it lighter, and trying out new materials as well as pushing sheet steel to its limits. “This is a huge step for us. Normally we work with sheets between 0.8 and 1mm thick and I would like to take it to somewhere between 0.4 and 0.6. That’s a 50 percent reduction in material!” Criticised in design circles for being a one-trick pony, Zieta admits that much of what he presents in Milan this year are “facelifted” versions of previous projects. Despite the refinements to Plopp of new materials and finishes, the stool still attracts attention thanks to its instantly recognisable form. The two new launches, a clothes hanger and coat rack, are the first products that people will be able to buy and inflate at home using a bicycle pump. Like the Blow and Roll installation at last year’s London Design Festival, “It uses the technique of rolling metal before inflating it as a way to stabilise form,” Zieta explains. “It’s a breakthrough for us. Our first real product to be made using rolling technology, that has an actual function.”

credit Zieta Prozessdesign On the architectural scale, the application of FIDU has been limited to the odd installation or pavilion – small-scale projects that have teasingly demonstrated the potential of the technology without progressing beyond the status of design fair showpiece. Most recently, Zieta completed a temporary bar in London for Ballantine’s whisky – a formation of stacked metal boxes that were crushed under pressure, to resemble ice cubes. “We reversed the technology here, so it’s implosion rather than inflation. We tried to do something that would push the limits of our technology.” Zieta splits his time between his native Poland, with a multi-disciplinary office in Wroclaw that includes artists, engineers, architects and designers, and Zurich. He describes ETH as his “scientific base, a place to research things, simulate and develop forms”. His radical approach to developing new technologies has inspired a whole generation of young Poles who are keen to establish themselves within the country’s emerging design scene. Conscious that he is widely regarded as a role model, he warns that his success has not been easy: “I want everyone to understand that my work is not some five-minute success. I don’t want to be a role model for creating forms but for the hard work and research I’ve been doing for years, and the risks I took to develop a new technology and to experiment with producing furniture in a new way.”

credit Zieta Prozessdesign |

Image Piero Martinello

Words Riya Patel |

|

|

||