words Justin McGuirk

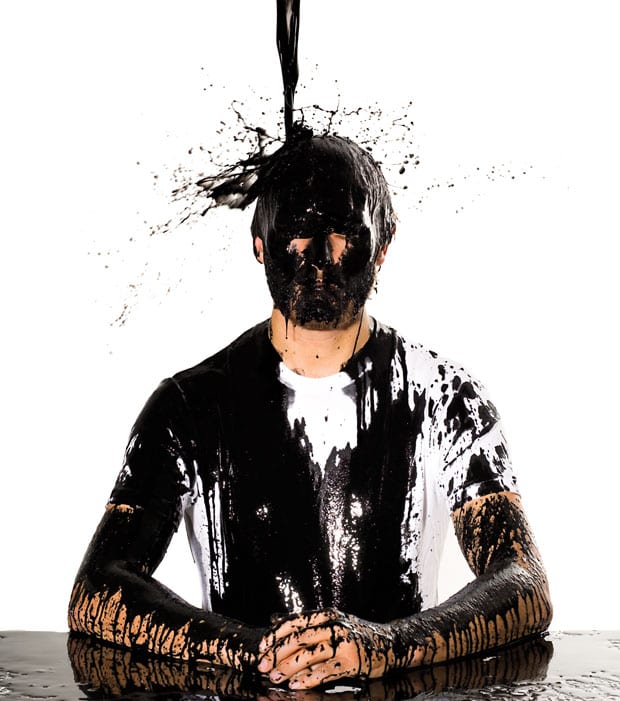

Don’t worry about oil running out it’s never going to happen. use more plastic it’s good for the environment. But don’t touch biodegradable plastics, they’re an eco disaster. Oh, and recycling is a waste of time.

Out it’s never going to happen. Use more plastic it’s good for the environment. But don’t touch biodegradable plastics, they’re an eco disaster. Oh, and recycling is a waste of time.

Worried about the oil crisis?

Then use more plastic. It sounds counter-intuitive, since if one is “running out” then so is the other. It also sounds provocative, because plastic has a reputation as a pollutant, heaped up in landfills.

But it’s the most energy efficient, eco-friendly material a designer can use. There’s just one problem. You know how cheap and disposable it is? Well, it’s neither of those things any more, and that means we have to completely rethink some of the basic assumptions of consumer society.

Everyone knows oil is a limited resource, but the truth is we were never going to bother imagining the consequences of our cheap plastic products until our wallets forced us to. Finally, that’s starting to happen. The recent oil crisis, in which the price of a barrel of crude doubled within a year, was the tipping point. For the first time, manufacturers using oil-based materials are starting to wonder how long their business models can last.

“Plastic has to become more expensive – everything that is based on oil will have to become more expensive,” says Dr Sabine Philipp of BASF, the world’s largest chemicals company. “In the end, all consumers and processors who are working with plastics will have to accept that.”

The problem is not that we may have reached our peak oil producing capacity, or that we will ever run out – as one oil executive pointed out recently, there’s no shortage of $300 barrels of oil. It’s that our transport and energy demands are driving the price sky-high, and that’s affecting the relatively tiny proportion we turn into plastic.

At the moment, only 4 per cent of oil is used for plastic, but that 4 per cent is the backbone of our consumer lifestyles. Plastic is the cheapest, most versatile material we have, and we can’t live without it. From products to packaging, it’s either in or around everything we buy. So where are we going to feel a price hike most?

BASF said it wasn’t able to say how much its plastics were going up, but some figures are publicly available. For instance, the price of its polystyrene – which is what your yogurt pots are made from – has risen €1400 per tonne to €1605 (15 per cent) since the beginning of the year. Now, a price rise like that isn’t going to ruin a manufacturer making injection-moulded plastic chairs by the thousand. But apply it to one producing shampoo bottles by the tens of million in a case where pennies make the difference between a product that is economically viable and one that isn’t, and you have a dilemma.

“That begins to have a serious effect on the client’s business model,” says Nick Talbot, a director at product design firm Seymour Powell, which is now being asked to reduce the amount of plastic going into even the caps of such shampoo bottles. He says that the high-volume packaging industry, forced by rising prices, is the most committed to thinking about this problem, and that that has only happened “in the past year or two”.

“When stuff is cheap, fine, make the cap as big and as complex as you want. But there has been a shift in emphasis to minimising the plastic used – partly it’s the cost, partly it’s the carbon footprint.”

So the situation is bad enough that we have to value-engineer our bottle tops. Yet, there is no feasible alternative to plastic for that kind of product. Even with rising prices, it’s still the cheapest and best-suited material for the job. It is also far and away the most energy efficient. Steel, for instance, which is affected even more by the price of oil, requires much more energy to smelt. Plastic is also much lighter, so the more you can use it instead of metal parts in, say, cars, the less fuel you’ll burn and the less greenhouse gases you’ll emit.

What’s more, plastic captures carbon rather than releasing it into the atmosphere, which is what happens when you burn oil. So if we can find a way of using it without throwing it away then it is actually a thoroughly benign material.

Plastic should be a green dream, but not the way we treat it, which is to use it for a few minutes, days or weeks and then throw it away. It has a bad reputation because it takes centuries (no one’s quite sure how long) to degrade, and so have become synonymous with images of tutti frutti-coloured dumps. “If we do a phone at the beginning of the year that will have a bunch of ABS and styrene – you know, a whole load of oil – in it, then at the end of that year it’s likely to be in a landfill somewhere,” says Talbot. “We’re not happy with that but it’s a reality of the world we’re living in.”

“A friend of mine just paid less than ten quid for a toaster and kettle from Woolworths, and he’s aware that that’s not sustainable,” says Sam Hecht of product design firm Industrial Facility. “He’s sound of mind and a perfectly conscientious person but he’s swayed by the cost. Once it becomes uneconomical for companies to maintain those prices then peoples’ minds will change.” But surely there are alternatives.

Forget about alternatives Weighing up the economic and environmental factors in the use of plastic is causing a huge amount of confusion. First, designers are coming under increasing pressure from manufacturers to use less plastic wherever possible because of the rising cost, but at the same they should be using plastic in more and more instances. If you find that confusing, then consider this: for several years now the design industry has been encouraged to adopt new bioplastics, which are plant- rather than oil-based, and biodegradable plastics, which contain salts that help them decompose. They sound good and have been touted as the eco-friendly option – the only problem is, they are worse for the environment than ordinary plastics.

“The way people have jumped onto biodegradable and bioplastics as being somehow eco-friendly is a nonsense,” says Colin Williams, who founded Smile Plastics, a recycled plastic manufacturer, 15 years ago. “On the vast majority of applications, if you do an audit, they come out as an eco nightmare.” The problem with bioplastics is that to make 200,000 tonnes of them requires up to 350,000 tonnes of crops, and since we’re also facing a food crisis, a significant adoption is going to mean that people will starve. Biodegradable plastics, meanwhile, release methane when they decompose, and methane has 23 times more impact on global warming than carbon dioxide.

Does anyone have a clue what to do?

Let’s assume that, given the opportunity, all designers want to do the right thing for the environment when it comes to choosing a material. In the face of so much conflicting information and complex carbon footprint calculations, how are they supposed to know what the right thing is? “It’s difficult to take a position because it’s difficult to feel that you’ve been informed correctly,” says Sam Hecht. “There are a lot of people telling you what you can’t do but no one telling you what you can do. There’s no one saying you can use plastics but

use these ones. There’s no knowledge being transferred.”

The UK government’s Department for Environment, Food and Rural Affairs (Defra) produced a report this summer on the sustainability of materials, but there was precious little in it about how and when to use plastic. “With plastics there’s no clarity about what you’re trying to cut out of the market,” confesses one of the compilers of the report, who didn’t want to be named.

So where are designers supposed to go for support? Where is the vision for a sustainable plastics culture supposed to come from? Hecht says clients like Muji and Herman Miller have information that has influenced his decisions. Jay Osgerby, of London design firm Barber Osgerby, points to resources such as Material Connexion and the Carbon Trust. And, like Hecht, he also looks to his clients, such as a drink manufacturer that recently approached the firm with a high-volume commission. “Bottling companies know intimately about innovations in the plastics world because it affects their business so intimately,” he says. So why is he considering using a bioplastic called PLA (made from corn starch) to produce that bottle?

Whose responsibility is the problem?

Ask a designer whose responsibility it is to tackle how plastics are used and you’ll get a politically correct response: it’s everyone’s responsibility. So you would have thought that manufacturers would be including some kind of sustainable directive when they set a brief. That wasn’t the case for any of the designers I spoke to. “The problem is that none of our clients are asking for that. It’s not part of their mandate,” says Sam Hecht. “If you make a radio no one is asking you to think about what’s going to happen to this radio when it’s life is finished.” For Hecht, it’s a case of the designer having to use common sense. For Osgerby, the sustainability message is implicit in any commission. “It’s one of the fundamentals of design development these days,” he says. Is it? What if the price constraints or the “brand message” don’t allow you to make the right decision. “What do you do? We’ve got to get on with the project,” says Talbot. Designers have to pay the rent too. Which is why many designers said they wished governments would put more pressure on manufacturers. The problem there is that governments don’t want to do anything that might inhibit economic growth. “If you made Apple take full responsibility for all the iPods they produce, where does that lead to?” asks Hecht.

Recycling is not the answer

If you think making a product recyclable is the answer, then you’re missing the point. “A lot of designers are trying to build recyclability into their designs, and I believe that should be down at the bottom of their list,” says Colin Williams. Recycling has captured the public imagination because it’s relatively easy to do, but it’s just a process of “waste diversion”, says Williams, and the system only comes full circle when someone buys a recycled product. And that’s by no means a foregone conclusion, either because it comes at a premium or is perceived to be tainted in some way or, at the higher end, is plain undesirable. “Designers on an environmental mission often forget that a large part of the product is about aspiration and pleasure,” says Hecht. “So-called sustainable design is often awful – a lot of people bang that drum but I’ve never seen anything I’d particularly want, it just doesn’t appeal somehow.” In any event, only 19 per cent of all our plastic waste is being recycled. And although the demand for recycled plastic from the packaging industry is growing exponentially, it’s just not translating to the product design industry. High-volume brands pump out products that can’t be recycled because they combine different plastics (like most toothbrushes) or use painted plastics (like any silver-looking TVs). There’s a way to avoid this, the so-called cradle-to-cradle system, in which plastic is uncontaminated by other materials and can be returned to make more of the same product. But that accounts for a minuscule percentage of the market. Even if manufacturers were willing to shift to that system, recycling is still

not the answer. If anything, it merely encourages disposability by making us feel virtuous about throwing things away. “It allows us to consume more and more – it’s not a great way of life,” says Hecht. The real solution is to convince people that plastic is a valuable material.

The goal for any designer now has to be to design out obsolescence. “We do our utmost to design things that people don’t throw away. That’s our bit I suppose,” says Jay Osgerby. From Sabine Philipp’s perspective, “It’s about keeping the oil in use as long as possible.”

If the initial consumer can’t keep using a plastic product, maybe someone else can. “The best recycling company in the world

is not BP, it’s eBay,” says Hecht. “Every time someone buys something that’s been used, it allows that thing to stay in circulation for another life.” If there’s any lesson to be learned from this debate, it’s that designers have to calculate the real ecological cost of a product from, to use the jargon, cradle to grave. Designers are going to have to become accountants, subjecting every stage of a product’s life to an “eco-audit”. “It’s very, very difficult,” says Colin Williams, “but more and more statistical tools are being made available so you can do a fairly crude eco audit on what you’re designing and all of a sudden it might make you change your mind. And that is the biggest change designers are going to have to go through.”

Systemic change

There’s one thing that everybody agrees on, and that is that there is only one way to ensure that we use less oil in our production methods and minimise the damage we do to the environment through waste: consume less. “Our generation is the last that will

have the luxury to buy and buy and buy things all the time. It’s our lifestyle that’s unsustainable,” says Williams.

The endless cycle of purchasing and discarding is absolutely fundamental to the capitalist economic system and our very way of life. For the time being, that system doesn’t seem to allow us make mobile phones and laptops with a useful life of more than two years. “It’s quite possible to make a car that will last for a million miles without any problem but it’s very much against Ford motor company’s interests because their sales will plummet,” says Williams. Businesses need us to throw things away so that we can buy more, and governments aren’t going to pressure businesses to change that because the one thing that governments treasure most is economic growth.

The paradigm shift is only going to happen when price rises force it to happen. And there are signs of that now, with the oil crisis raising the price of almost every product imaginable. The designer’s role in all this is to be persuasive. “How you do that is actually a designer’s job: to convince people that they should buy something with a higher inherent value and hold on to it for longer,” says Nick Talbot. And there’s only one force that can persuade companies that longer lifecycles are the way forward, and that’s the purchasing power of consumers – or, rather, the purchasing restraint.

So you think there’s no oil in these?

Heart valves and bullets

Most prosthetic heart valves consist of a metal ring coated with polytetrafluoroethylene (PTFE) fabric, aka Teflon, the cunning non-stick coating found on frying pans – and also used to cover the glass-fibre fabric of the Millennium Dome. PTFE is also found in body piercings and used to coat certain types of hardened, armour-piercing bullets, so as to reduce the amount of wear on the firearm’s rifling.

windows

Originally devised by Englishman Frederick Walton in 1860, real linoleum is made from solidified linseed oil in combination with wood flour or cork dust over a burlap or canvas backing. Despite being sold under the same name, it has been largely replaced with the brighter and less flammable polyvinyl chloride (PVC), a material which sneaks into our homes in many other guises, as window frames, waste pipes, drainpipes, gutters and downpipes.

Beer

Seemingly devoid of oil-sourced materials, most canned beer conceals a plastic widget, while even glass bottles with metal caps incorporate a cap liner, made from ethylene vinyl acetate (EVA) – often gobbled up by fish, mistaking them for tasty baby jellyfish. Powdered in medicinal compounds, EVA is used to slowly release drugs over time, while in its foamed form it is injection moulded to make the ubiquitous Crocs sandals.

paper Cups

Think paper cups are oil-free? These eco red herrings are actually waterproofed with a low density polyethylene (LDPE) lining, the same thermoplastic coating used in milk, juice and soup cartons, and also the basis of many computer components and plastic bags.

Magazines, medicines and matches

We try to be eco-friendly, but this magazine is an oil-guzzling monster. Our printing inks contain petroleum-based solvents to make them flow better, and these pages are bound in an EVA-based glue. The same petroleum jelly is often used in medicines, toiletries and moisturisers, while in wax form provides the basis for candles, shoe polish and matches.

Oliver Wainwright

All images: Andrew Penketh